Alternate chainplate design ideas

July 4th, 2010 | by Van | Published in Rigging | 1 Comment

Looking forward, it’s pretty clear that eventually our chainplates will need replacing. Crevice corrosion is almost impossible to stop, and is likely to lead to eventual failure. Whether that is one year from now, or twenty is not clear. We still have nine more chainplates to pull – the first three showed modest corrosion. What if we pull one and it’s in terrible shape??

Marten wrote us a note recently about the chainplate design, saying that he was considering replacing the hairpin design on his boat with a simpler one, because the fabrication costs of the hairpin were pretty high. He was proposing a chainplate based on a flat plate that would sit on the deck, with two long bolts replacing the hairpin rods, and a tab welded to the plate that would provide the hole for the shroud.

A problem with the design is the weld – any time you have a weld, you are increasing the chances of problems. Firstly, the welding process heats the metal to its melting point, allowing changes in the composition (Marilyn tells me it’s actually the crystal structure that changes – and that’s was matters!) of the alloy (invariably making it more susceptible to corrosion). Secondly, it’s highly likely that the weld will leave micro-cracks or crevices that will be ideal spots for crevice corrosion to thrive. Not a good recipe for a long term solution.

So, that set me thinking about a better design, starting with Marten’s ideas about using standard parts with bolts to connect to the hull. The design goals would require the chainplate to be of an appropriate strength, but easy to manufacture, and without imperfections that would encourage corrosion.

An alternative to the T design that Marten suggested is an L – i.e. what a machinist would call a 90 degree angle.

There is a subtle design issue here – if the shroud is pulling the top of the L or T even slightly inboard or outboard, then a potentially large torque on the part is created. A torque is a bad thing because it causes the heel of the L (or T) to act like a fulcrum, which concentrates the forces into a compression force on the deck and lifts the opposite edge of the plate. As the shroud goes in and out of tension as you tack, this wobbling back and forth is going to lead to a leak or a loose chainplate.

However, it is possible to design the L (or T) so that the shroud does not apply a torque to the part. Intuitively, you can see it this way – suppose the shroud comes in at an angle too low. The result will be the top of the L being pulled inboard. Well, suppose you could have the shroud coming in from outboard, then the torque would be outboard. So, there must exist some angle for the shroud where inboard switches to outboard – in other words the torque is zero. Put another way, for a given shroud angle, there must exist some configuration of the L such that the torque is zero.

In fact, it’s easy to see what that angle is. It’s simply the case where the attachment point of the shroud to the L (or T) is precisely aligned with the point on the foot of the L where the bolt to the hull is. (One can also show this mathematically, I can send you the details if you want). So, if you can construct the chainplate to have that magic angle, then you eliminate the torque and reduce the chances of leaks and loosening. Eliminating leaks of course helps eliminate a major source of crevice corrosion in the hidden bolts that go through the deck.

From a materials selection and fabrication point of view, using a T is problematic because in most cases (as far as I can tell from looking at sources such as McMaster-Carr), the T is made by a welding process. However, an L is not – it is made and annealed as a single piece.

Sizing the chainplate is an important task as well. To do this, I referred to Brion Toss’s book, The Complete Rigger’s Apprentice. This is a superb, practical book, even if you are not going to re-rig your boat yourself – it certainly will help you understand what’s needed. It’s also a good read, and a must have for your cruising library.

Toss describes on p150 how to estimate the breaking strain for your chainplate – basically, calculate the cross sectional area of metal supporting the shroud, and multiply this by 80,000 lbs/inch2. He also gives a table by Skene that shows for a given wire diameter, the size of the chainplate required. Rainshadow uses 9/32 inch cap shrouds that have a breaking strain of just over 10,000 lbs. Skene recommends 5/16 inch plate thickness, which is not a common size for 90 degree stock. So I would use 1/4 inch nominal thickness stock, and beef up the lateral size (Skene calls this the radius B) to meet the strength requirement.

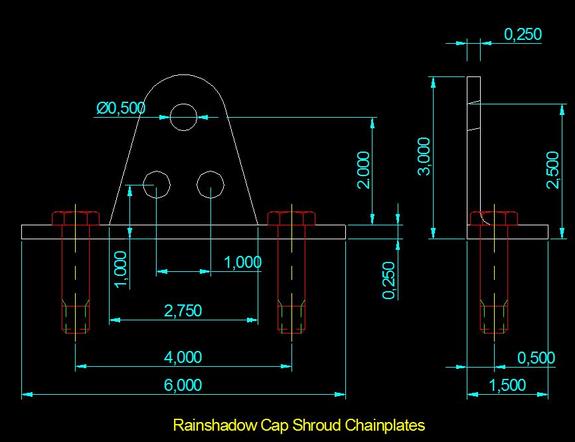

Above is a rough sketch of the chainplate – before I’d build this I’d want to re-run the numbers. On our Nic 38, the cap shrouds intersect the deck at an angle of about 80 degrees. The lower shrouds are closer to 70 degrees.

I’ve assumed we are starting with a 3 inch 90 degree angle of thickness 0.25”, made of 316 stainless. I can’t find one of these in titanium unfortunately – Ti doesn’t suffer from crevice corrosion. The bolts are 1/2 inch titanium hex head bolts. They’ll run about $15 each, but we’ll never have to worry about crevice corrosion of the bolts again. I’ve added two holes in the lower part of the upright, to allow us to fit blocks to the chainplates (eg for mizzen staysails, preventers, etc). The bolt is set close to the inner edge – it’s centered 0.5” from the edge, and with the shroud hole being 2.5” from the base (that is to the upper edge of the hole), that gives an angle of about 11 degrees, which matches our cap shrouds.

This L-shaped chainplate should be pretty easy to make. If I had access to a mill, even I could make it. In a pinch, you could make it with a hacksaw, a drill and a file. None of the dimensions are especially critical. One tricky bit is that the chainplate hole should be drilled at an angle of about 10 degrees as shown. This makes the pin align better with the angle of the shroud (so that it’s not resting on edge).

I’d be very interested if anyone has tried anything like this or has any other comments.

Update April 2012:

After much thinking about this, I’m really inclined to stick with the original design, with one change. The welded on “beauty plate” that mates with the deck adds no structural strength to the chainplate, so instead of welding it to the hairpin as in the original design, I’ll just have it made to loosely slide over the hairpin, and I will simply glue it in place with Sikaflex or similar adhesive. This should eliminate an unnecessary and probably costly weld step in the fabrication. This also makes it easier to think about making the hairpin out of titanium rod.

November 29th, 2011at 12:47 pm(#)

Your statement that the plate cannot be done in Ti (G5) is not true. Your plate can easily be made of Ti as shown. The price difference is not too much as a Ti plate would cost around 3x of SS304 and about 1.5x the price of SS316L, certified materials, where the 316L is a high PREN valued metal (a higher Cr and Ni content 316L, but 2x the price of ‘cheap’ 316). Welding with 316 and 304 will create heat affected zones where the metal will not properly produce a protective oxidized layer and cannot protect itself from future chlorine ion attack (~2 ppm in equatorial sea water). Ti doesn’t have the negative effects of a heat affected zone, so this part could easily be butt welded in Ti. The strength is 90% at the Ti weld and there is no issues with crevices in Ti welds. Looking at the number from Skene, the part in welded Ti (G5) could still give you a better than a 300% ‘over engineered’ part in UTS and UYS (actually ~600% in UYS). You’ll note that in Skene only UTS is considered as the plate should be correctly aimed at the tang, but UYS is still a consideration in his calculations when he later considers dynamic loading during movement of the entire vessel. Either way, a welded Ti part is still far superior than a ‘yielded’ (90 bend) 316L part (cold rolled or otherwise, due to crystalline breakdown at the apex of the bend leading to crevice issues in SS316, both ‘yielded’ and ‘extruded’ stock). But the PREN values of 304 in equatorial service of non submerged parts is about 15 years (temp is important and natural SCC starts in 304 at a mere 70 degrees) and 316 with a high PREN value is nearly double that at 30 years (where SCC starts in 316 at around 80 degrees). Then the real question, provided ‘all’ metal considered have the right ‘finished’ UTS, is how long do you need the part to last, versus how much money do you want to spend? Obliviously if you spend too much on the chainplates and not enough on the other components of the entire system, then who cares if the chainplates last a thousand years? But if you’re going to be sailing this boat for more than 25 years, and don’t want to be changing your chainplate say when you’re possibly 90 years old, then perhaps a set of nice Ti chainplate is well worth the money.